July 2016, Government Fleet – Feature

|

The week of June 20 was a great one for the City of Columbus, Ohio, and its fleet.

Reagan was there to accept the award on behalf of the entire fleet operation, but he immediately told his colleagues who weren’t there. Reagan called his staff members and the director of finance. Both fleet operations managers found out at home after receiving a text of a photo of Reagan holding the two awards.

The Leading Fleets award, sponsored by Ford, recognizes public fleet operations that demonstrate innovative leadership, operational efficiency, vision for the future, and successfully overcoming challenges. Five industry professionals judge the award, which is open to public fleet operations in the U.S. and Canada. Columbus was named the No. 1 overall fleet as well as the No. 1 Large fleet (more than 1,000 assets). Columbus’ total fleet size is more than 6,200 units.

A Leadership Role

One of the main criteria for the award lies in displaying leadership, both within fleet operations and the community. One area where Columbus leads the way in Ohio is in compressed natural gas (CNG) use and infrastructure. In fact, Fleet Operations Manager Bill Burns’ job evolved from a shop management role into an infrastructure role shortly after the city began its investment in CNG. He now mainly spends his time overseeing fueling infrastructure, reducing the number of unleaded and diesel fueling stations from 56 to 43 in eight years. Burns also managed the construction of two CNG fueling sites, with one additional fueling station set to begin construction in the next few months.

Since opening, the two CNG fueling stations have pumped more than 1.5 million gasoline gallon equivalent (GGE) of CNG for both city fleet and retail customers, Burns said.

The City of Columbus led the charge in the Ohio area with its investment in CNG, and interest in the alternative fuel is growing in the state. Just as the Columbus fleet team gained assistance from the City of Culver City, Calif., during its CNG transition, Columbus is now able to advise neighboring fleets switching to natural gas.

“Other entities are asking for our input in alternative fuels, and we are assisting them in any way we can,” Reagan said. These include the cities of Hamilton and Waco in Ohio, as well as Ohio State University.

“Many municipalities will ask us for our specifications for CNG, because maybe they haven’t built a CNG truck before. They’ll either ask for our specification or piggyback off our contract,” John King, fleet operations manager, added.

|

Burns, now working on his third CNG station and overseeing the operation of the existing stations, has become a CNG infrastructure guru.

“By default,” he added.

Another area where the fleet shows leadership is in training. Through the Ohio chapter of the Municipal Equipment Maintenance Association (MEMA), the city has led and hosted numerous training sessions for its technicians as well as others in the area.

“We had a goal to do 12 trainings for the year, and we far exceeded that,” King said. In 2015, the city hosted 16 training events where technicians from other municipalities were invited to attend. Reagan estimated about 300 technicians received training from these events throughout the year.

Topics include training on CNG tank inspections, garbage truck maintenance, and Emergency Vehicle Technician (EVT) certifications — staff also proctored exams so technicians could take EVT tests afterward.

Staying Competitive

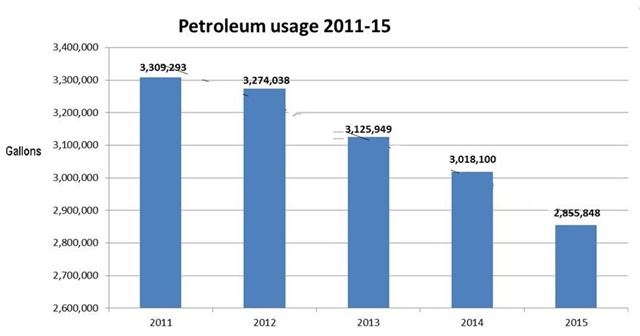

The city wanted to reduce fuel consumption, and its goal is to reduce petroleum fuel use by 1 million gallons, measured in a single year, by 2020. The “one million gallon challenge” uses a benchmark year of 2010, and in 2015, the fleet had reduced its fuel use by 599,524 gallons. This isn’t an overnight success, but a gradual decrease of petroleum fuel use every year, Reagan said (see graph below). To reduce petroleum fuel use, the division worked on right-sizing the fleet and purchasing more “green” vehicles, including those that run on CNG.

The use of the anti-idling system on police vehicles has also contributed to the fuel use reduction. According to King, GPS data showed the police fleet idled 50% of the time. He and Eric Voll, automotive mechanic supervisor II, talked to various vendors to find an anti-idling device that would work for the city’s needs. Voll, who plays a major role in everything fleet does with police vehicles, led the installation of the GRIP idle system on patrol vehicles for the pilot and captured the data. The system automatically turns off the engine once idling exceeds a certain amount of time, but does not affect auxiliary equipment such as radios or computers. With this data, the city found it reduced idle time by 26%, which equates to a savings of about 758,200 miles. Fleet and the Police Department made the decision to expand the program.

“With Eric and John’s leadership, we were able to bring Police along and involve them in the entire process, and get their buy-in to the point where they own it,” Reagan said.

As for competitiveness and efficiency, the fleet continues to benchmark its numbers using Utilimarc, a fleet management software company. Its data shows the city fleet is performing better than the industry average for the number of weighted vehicles each mechanic is supporting, the number of weighted vehicles for support staff, and technician costs per hour. Additionally, it compares its labor rate with the local average rates, coming in 28% lower than the local average rate for heavy trucks and 31% lower for light vehicles.

|

Reagan is confident the fleet will meet its million-gallon challenge. CNG will contribute to a large chunk of the reductions — the city is on pace to pump 400,000 GGEs of CNG this year. Additionally, the Smart City Challenge will provide the city with the means to purchase 200 electric vehicles and charging infrastructure. This will help Columbus further reduce petroleum fuel consumption and will be another area of leadership for the city. Columbus beat 77 other cities in the national challenge, and in addition to the fleet of electric vehicles, the city also proposed three electric self-driving shuttles, smart lighting on streets, and an app for real-time traffic and parking updates.

Valuing Staff Contributions

Every person on the 121-member fleet team contributes to the award, whether that’s in being efficient technicians, implementing greening plans, changing up police vehicles, or pulling data to make sure everything is going as planned.

“I’m on the floor every day, and [the technicians] are proud to have our names out there in the papers,” said Deryl Seward, assistant operations manager. “The guys are really excited about the award.”

The management team works hard to make sure everyone’s voice is heard, and they’re able to shift responsibilities as changes arise. The city tries to promote from within. Burns was previously the only fleet operations manager, but as his role shifted more toward fueling infrastructure management, King was promoted to the same title to oversee operations. Seward was promoted to replace King.

Staff members are encouraged to share ideas for workplace improvement and cost savings. Recently, two supervisors submitted a cost-saving idea to switch tire compounds on heavy trucks. After conducting a two-year experiment on a more expensive tire compound, they noticed tire performance had improved so drastically that it resulted in an annual cost savings of $66,800. In 2015, they were each rewarded with $1,750 as part of the mayor’s awards.

To celebrate the No. 1 fleet win, the fleet division will host a lunch in September. Reagan will invite the mayor, city council members, and the director of finance. As is customary, management plans to serve lunch to the staff.

“As managers, we know the award isn’t about us. It’s about our success as a team: our mechanic and body shop technicians, our office and support staff, and our parts room employees. They’re the ones who make us successful,” Burns said.